| Thermal Insulation |

|

|

| To be cost efficient, refrigerated truck bodies must be insulated effectively and reliably whilst also being lightweight and built with highly durable materials to last for decades. The good thermal performance of a refrigerated truck should be maintained over the lifetime of the vehicle, requiring that the body elements don't pick up moisture. Using insulation core materials in the production of refrigerated truck bodies helps meet all these requirements. |

| Polyurethane systems are tailored and

available globally to allow our customers to meet and anticipate the

most stringent regulations with a unique combination of superior

insulation efficiency, lightweight, structural bonding properties, and

ease of use. Current and future regulations, protocols and

international standard drive the production of professional appliances

to Zero Ozone Depletion Products (Montreal) and Low Global Warming

Potential e.g. greenhouse gases. |

| Protect food from field to table with Dow advanced insulation technologies |

|

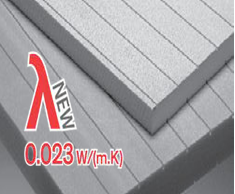

| Dow step changing XPS insulation for refrigerated trucks Dow XPS insulation boards properties like excellent thermal insulation, high mechanical strength, good bonding, high water and vapour resistance, lightweight and long-term performance, makes it a great insulation core material for the refrigerated trucks industry. Opting for Dow's new generation of XPS as the core layer material for sandwich panels means opting for long-lasting effective thermal insulation. |

|

®™ Trademark of The Dow Chemical Company ("Dow") or an affiliated company of Dow

Copyright © The Dow Chemical Company (1995-2025). All Rights Reserved.

|

| Whether your process needs an extruded polystyrene (XPS) foam or injected polyurethane (PU) insulation, Dow has a solution to suit your needs. |

|

| Dow polyurethane Injection offers greater flexibility to the production process |

Key benefits:

|