| Improve the sustainability profile of your tablet coating process with METHOCEL™ Premium VLV |

| The sustainability profile of the coating process can be improved with METHOCEL™ Premium VLV, compared to an E-LV based coating system, through reduced coating temperature and a shorter coating time. This leads to: |

|

If this message does not fit your application needs, please click here to share your areas of interest to receive information that is relevant to you. *Excluding coating material costs. These figures are based on a model with assumptions, including the application of a single coat. Actual figures may vary given a customer’s specific operation, but fundamental productivity advantages should still hold. |

| © Copyright The Dow Chemical Company 2012. All Rights Reserved. ™*Trademark of The Dow Chemical Company (*Dow) or an affiliated company of Dow |

| Find out more about how you can reduce coating time, increase productivity and reduce the total tablet manufacturing* costs by at least 27% per batch. |

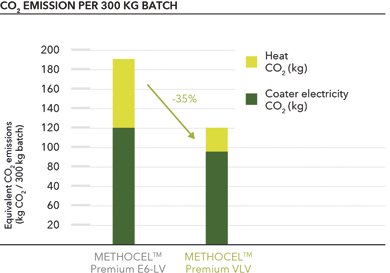

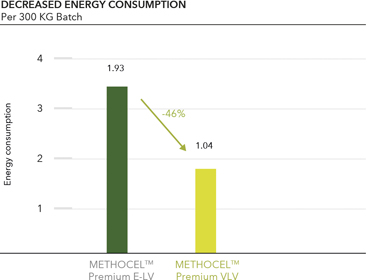

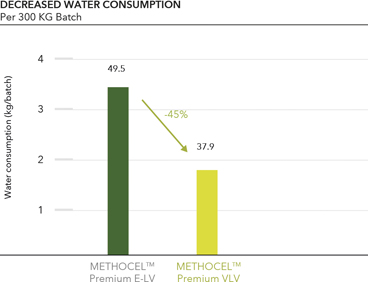

| Reduced energy consumption by nearly 46% per batch. 19% reduction in electricity consumption and a 66% reduction in heat energy used in each coating run, which in turn reduces CO2 emission by nearly 35% per batch. CO2 equivalents are calculated based on ratios provided by The Carbon Trust (London, UK)**. A higher concentration of solids allows reduction of the water used during the coating process by nearly 45% per batch. |

| ** CO2 equivalents are calculated based on ratios provided by The Carbon Trust (London, UK) Electricity: 0.5246 kg CO2/kW-hr Steam (natural gas): 0.1836 kg CO2/kW-hr |