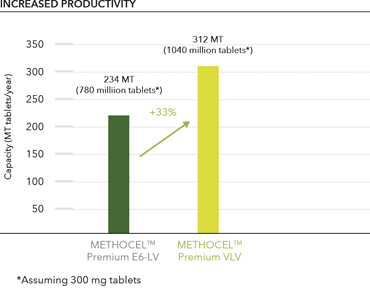

| Increase productivity by 33% with METHOCEL™ Premium VLV |

| Thanks to a reduced coating time, productivity and subsequently capacity can be increased. This means that 33% more tablets can be coated in the same amount of time and that capital investment can be delayed. |

|

If this message does not fit your application needs, please click here to share your areas of interest to receive information that is relevant to you. *Excluding coating material costs. These figures are based on a model with assumptions, including the application of a single coat. Actual figures may vary given a customer’s specific operation, but fundamental productivity advantages should still hold. |

| In addition, the need for capital investment to purchase new or additional coating equipment can be delayed. |

| Find out more about how you can reduce coating time, improve your sustainability profile and reduce the total tablet manufacturing* costs by at least 27% per batch. |

Solution delivery (SLD) (only delivery aspects, not incl. preparation) Coater and SLD Coater, SLD and infrastructure Add solution preparation Coating system Integrated coating system |

| Components Pump(s); flowmeter(s) manifold; nozzles Coater, bypass Air handler (inlet and exhaust), material handling (load and unload), WiP Tanks, mixers Controls, recipes Automation, data management, integration |

Average sell price (K$) 50-150 150-500 250-800 150-300 (add) 300-1,000 500-1,200+ |

| Calculations show that a reduction of the coating time leads to a significant increase in capacity. That means that 33% more tablets can be coated in the same amount of time. |

| © Copyright The Dow Chemical Company 2012. All Rights Reserved. ™*Trademark of The Dow Chemical Company (*Dow) or an affiliated company of Dow |